Чем светоотражающая пленка Diamond Grade отличается от стандартной светоотражающей пленки?

Время выпуска: 14 октября 2025 г.

Оглавление

В современном мире безопасность и видимость являются ключевыми факторами в сфере транспорта и общественной инфраструктуры. Будь то дорожные знаки, строительные ограждения или разметка, светоотражающие материалы играют важную роль в обеспечении безопасности на дорогах, особенно в ночное время или в непогоду. Среди множества видов светоотражающих материалов, светоотражающая пленка алмазного класса Отличается высочайшей эффективностью. Но чем именно она отличается от стандартной светоотражающей плёнки?

1. Технологии, лежащие в основе

Основное отличие заключается в структуре отражающего слоя.

В стандартных светоотражающих плёнках обычно используется технология стеклянных шариков, в которой крошечные стеклянные шарики отражают свет обратно к источнику. Это обеспечивает базовую видимость, но снижает яркость с увеличением расстояния или угла обзора.

В отличие от этого, светоотражающая плёнка алмазного качества использует микропризматическую технологию — структуру из небольших, точно спроектированных призм, которые отражают свет более эффективно. Эти призмы возвращают свет к источнику с гораздо большей интенсивностью, даже с больших расстояний или в условиях слабого освещения. Именно поэтому дорожные знаки, изготовленные из материалов алмазного качества, остаются яркими и чёткими ночью, в дождь и туман.

2. Яркость и видимость

Разница в яркости между этими двумя типами колоссальная.

Светоотражающая пленка алмазного класса может быть в 10 раз ярче стандартной светоотражающей пленки инженерного класса.

Например, стандартный светоотражающий дорожный знак может казаться тусклым или трудночитаемым с расстояния 100 метров в ночное время, в то время как знак алмазного качества остается четким и видимым с расстояния более 300 метров.

Благодаря улучшенной видимости водители могут раньше распознавать знаки, что обеспечивает большую скорость реакции и снижает количество аварий — основная причина, по которой многие правительства теперь требуют использовать материалы алмазного класса для важнейших дорожных знаков.

3. Долговечность и устойчивость к атмосферным воздействиям

Еще одно большое преимущество светоотражающая пленка алмазного класса является его долговечность.

Она изготовлена из высококачественных полимеров и покрыта УФ-устойчивыми материалами, которые защищают от солнечного света, дождя и экстремальных температур. Стандартные светоотражающие плёнки могут выцветать или отслаиваться через несколько лет, в то время как плёнки Diamond Grade могут служить до 10–12 лет без существенной потери яркости.

Длительный срок службы делает их идеальными для использования на автомагистралях, в аэропортах и на объектах, находящихся под открытым небом, где затраты на техническое обслуживание высоки.

4. Реальные приложения

Светоотражающие пленки алмазного класса в настоящее время широко используются в:

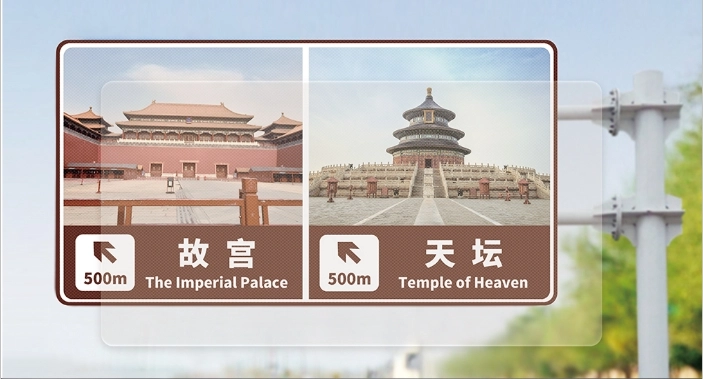

- Дорожные знаки для автомагистралей и городов

- Маркировка транспортных средств и номерные знаки

- Строительные и защитные ограждения

- Указатели для морских и аэропортовых сооружений

Например, город, модернизирующий свою систему безопасности дорожного движения, может заменить старые светоотражающие знаки на знаки класса Diamond Grade, чтобы обеспечить хорошую видимость в любую погоду, тем самым повышая общественную безопасность и снижая потребность в частой замене.

5. Стоимость против долгосрочной ценности

Хотя светоотражающая пленка для знаков алмазного качества изначально они стоят дороже, чем стандартные типы, но с течением времени окупаются лучше.

Его превосходная яркость снижает риск несчастных случаев, а длительный срок службы сводит к минимуму расходы на обслуживание и замену, что делает его более безопасным и экономичным выбором в долгосрочной перспективе.

Заключение

Разница между светоотражающей пленкой алмазного класса и стандартной светоотражающей пленкой заключается не только в яркости — она касается безопасности, производительности и надежности.

Благодаря микропризматической конструкции, исключительной долговечности и исключительной видимости светоотражающая пленка Diamond Grade стала предпочтительным выбором для современных проектов по обеспечению безопасности дорожного движения по всему миру.