الحرفية وراء كل ملصق عاكس

وقت الإصدار: 2025-09-02

هذا الصيف، تلقينا طلب عينة من عميل من الشرق الأوسط - سهم أصفر فلوري وأسود ملصقات عاكسة متوفرة بثلاثة أحجام: 5×90 سم، 10×90 سم، و15×90 سم.

في البداية، استخدمنا طريقة أسرع: طباعة الأحجام الثلاثة معًا على قالب واحد، ثم تجفيفها وقطعها بالأبعاد المطلوبة. كانت العملية سريعة، وساعدت الأوراق الأكبر حجمًا على منع التجعد. ولكن كان هناك تناقض - إذا تحركت الطباعة ولو قليلاً، بدا القطع النهائي غير متساوٍ.

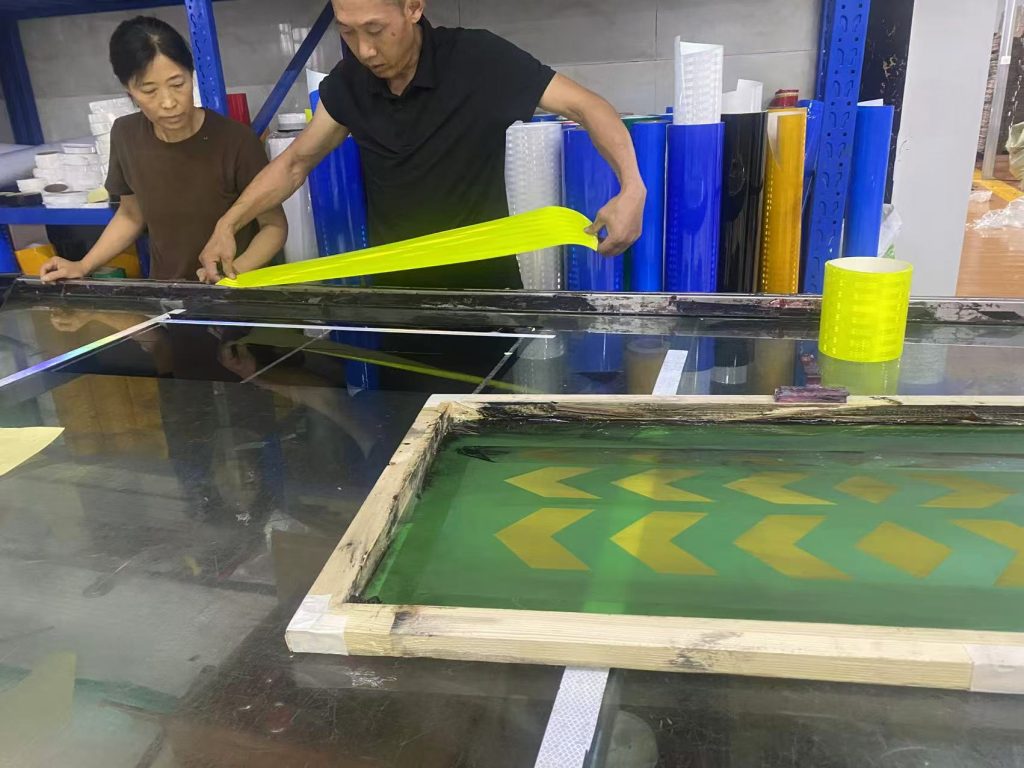

بالأمس، طلب عميل آخر ملصقات الأسهم نفسها. هذه المرة، تدخل مدير مصنعنا بنفسه. اختار أسلوبًا أبطأ ولكنه أكثر دقة: الطباعة الحريرية اليدوية.

أولاً، تم قطع كل ورقة إلى الحجم الدقيق.

تم تغطية المناطق غير المستخدمة بعناية بشريط لاصق.

تم تثبيت الورقة بشكل مسطح على الزجاج، مع محاذاة القاعدة الصفراء الفلورية والسهام العاكسة السوداء بعناية.

تعديل بعد تعديل، حتى أصبح كل سهم في المنتصف تمامًا.

وبعد ذلك، باستخدام ممسحة، تم ضغط الحبر من خلال الشاشة - بحركة ثابتة - وعندما تم رفع القالب، ظهر ملصق خالٍ من العيوب.

بعد التجفيف، غُسلت الشاشة، وأُزيل الشريط اللاصق، وتكررت العملية للأحجام الأخرى. كانت العملية أبطأ وأكثر تطلبًا. لكن النتائج كانت تستحق العناء - ملصقات أنيقة واحترافية، يُمكننا إرسالها بكل فخر كعينات.

بمشاهدتي المخرج وهو يكرر هذه العملية بصبر ودقة، أدركتُ أخيرًا المعنى الحقيقي للحرفية. الطباعة الحريرية اليدوية ليست مجرد تقنية، بل هي التزام بالجودة. كل تفصيل مهم. كل طلب، مهما كان صغيرًا، يستحق منا بذل قصارى جهدنا.

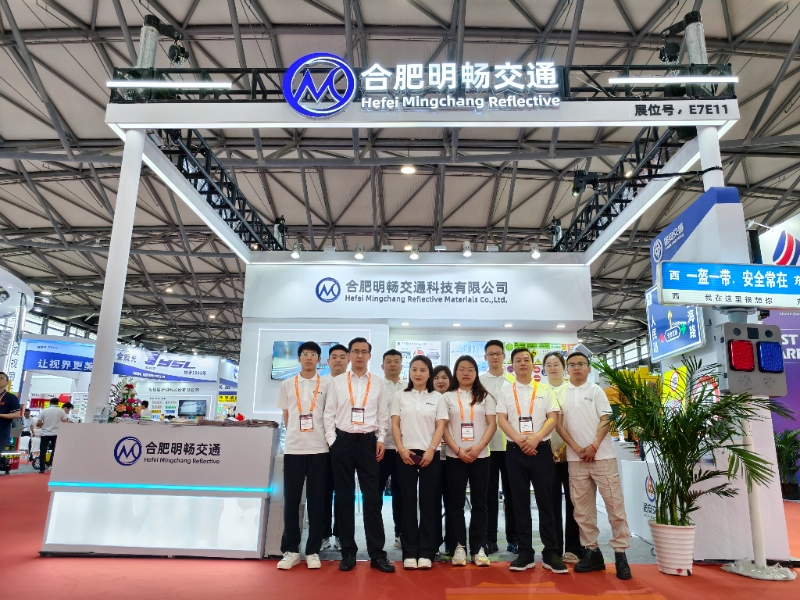

عندما يطلب العميل عينات، لا نكتفي بالتوصيل، بل نوصلها بكل حب. خفى مينجتشانغ الفيلم العاكس يعني اختيار راحة البال. فالجودة بالنسبة لنا ليست فعلًا، بل عادة.